sixgunrunner68 said:

Nice job Big!

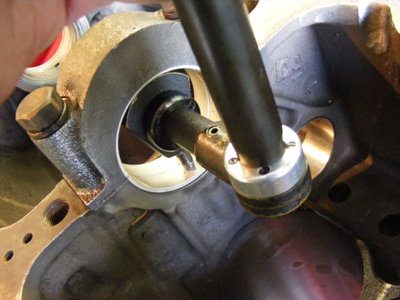

I would guess threaded on the filter tube. From a production stand point, I think it (but who knows from way back) would be easier to have someone thread it together than to press it. Not to mention limiting serviceability. Slide a punch through those side holes and see what happens. It's a 50 50 shot right?

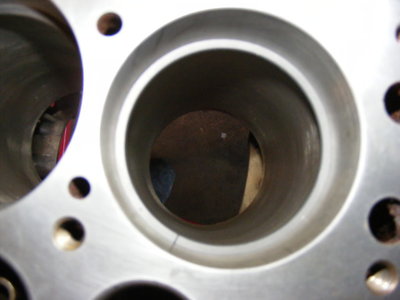

It doesn't seem to come apart. This is kind of a rare piece and I don't want to screw it up, so I posted on an old Mopar forum and no one else has figured it out either. Everyone that responded said they have just cleaned it the best they could by soaking it in solvent. The good thing is the tube is after the filter, so it doesn't have the sludge that the rest of the engine did.

I like the look of that cleaned up engine and the updates you are adding will really pay off when it's up and running.

I like the look of that cleaned up engine and the updates you are adding will really pay off when it's up and running.